Sign up to be notified of our new blog posts.

Why Do We Design Tanks with Coil Jackets?

Posted on July 10, 2019

Summary: The Uniflow Jacket = Faster, More Consistent Batches

Batch operators across the food, pharmaceutical, cosmetic, and chemical industries all measure success by two key outcomes: Throughput and consistency.

To improve both, while reducing operational costs, Lee Industries developed one of the most significant innovations in our 100-year history: the Uniflow Jacket.

This unique coil jacket design dramatically improves thermal transfer performance, helping you process more product, more consistently, in less time, without compromising quality.

Capitalizing on two fundamental truths about processing with jacketed tanks.

Let’s start with two fundamental batch processing premises:

- The more precisely you control temperature throughout all areas of your vessel, the more consistent your product quality and operational performance will be.

- The faster your vessel achieves these precise heating and cooling temperatures, the more product you can produce in a given time period.

The Challenge: Heat Transfer Bottlenecks in Traditional Jackets

In conventional jacketed tank designs, steam or water flows through dimpled jackets or standard jackets to heat and cool the interior wall of the vessel. In the 1960s, Lee engineers noticed shortcomings in these designs that were causing longer than necessary heating and cooling times. The jacket geometry allowed for the formation of air gaps, causing the jacket media to follow the path of least resistance. The irregular flow produced the formation of random hot and cold spots, resulting in inconsistent heating and cooling of the vessel wall.

The Innovation: Lee’s Uniflow Jacket

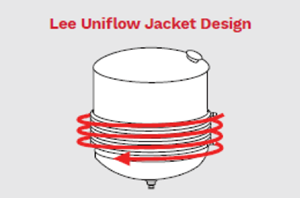

After researching techniques the chemical industry developed to accommodate high-temperature reactions, our engineers created the initial design of the Uniflow jacket, an innovation where steam or water is delivered to the jacket inlet with high flow velocity in a single direction through a tightly wound, stainless steel coil continuously welded to the side of the tank.

Performance Comparison: Faster Batches, Greater Output

This was a significant performance breakthrough that is still unique today. It starts with an innovative proprietary, specially formed 120-degree coil design that maximizes the heat transfer surface area and provides additional strength. This allows for a thinner inside wall, thereby accelerating heating and cooling to the interior wall of the vessel. Moreover, the coil’s unidirectional flow eliminates air gaps and hot/cold spots that can occur in dimple and standard jacket designs, which makes it possible for Uniflow-equipped vessels to generate faster and more uniform heating and cooling in every batch cycle.

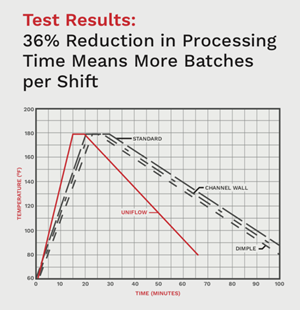

Tests comparing the performance of this Uniflow jacket design on a 1,500-gallon tank with conventional jacket designs have shown an approximate 36% reduction in total processing time. To put that into practical terms, in the same time it takes to run three batches in a standard, dimple or channel wall jacketed vessel, you could run four batches in a Uniflow jacketed vessel.

Ongoing jacketed vessel innovations

Since its introduction, Lee engineers have continued to refine the Uniflow jacket, delivering even more value and longevity to batch processors. We’ve made the coils thicker to reduce the stress impact of rapid temperature variations. We’ve added selective heating and cooling zones to improve efficiency and product quality when producing smaller batches in a larger-sized vessel. For processors that have intense temperature fluctuations, but require the functionality of a kettle, we can add the Uniflow coils to the outside of the cylindrical area of a Lee hemispherical kettle.

While we’re grateful that our coil-wrapped tanks have become somewhat iconic, recognized for their unique look, we’re even prouder of the performance boost they deliver. And you can be sure that our engineers are working hard on other innovations to help our customers improve throughput and consistency in their operations.

Get more information on Lee’s Uniflow Jacket here. Or contact us if you have a question or challenge that we can help you solve.

Last Updated: 10/17/2025

Comments

Add Your Own Comment