Sign up to be notified of our new blog posts.

Use the 10X Rule to Guide Your Food Production Expansion

Posted on April 30, 2018

Summary:

Your food product is taking off and you need to increase your production capacity to keep up.

If that is your situation, you may be asking a fundamental question to determine your processing equipment needs:

How much capacity can I get from each processing kettle without affecting my product’s quality or consistency?

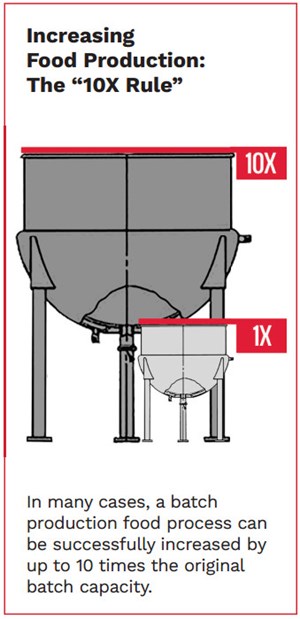

As a rule of thumb, your original batch processes can be expanded by approximately 10 times without adversely affecting your product.

This is called the 10X Rule.

So, if your current batch production capacity is 100 gallons in a 100-gallon kettle, by following the 10X Rule you could scale your production up to 1,000 gallons in a 1,000- gallon kettle with no significant negative effects.

Pretty simple, right? Not so fast. You should first know that for some applications, scaling up to a much larger kettle capacity can bring some complications.

When Product Characteristics Influence Scaling Limits

Some food products, like soups, salads or pie fillings use chopped vegetables, beans or fruit that must remain intact through their cooking and mixing. If these ingredients are processed in too large a kettle, the pressure of the mass at the top of the vessel (the “head weight”) can crush other ingredients at the bottom.

Likewise, some craft or homemade-style operations may require the attention of individual chefs throughout production, carefully assembling, mixing, cooking and monitoring each batch.

Simply expanding to a larger kettle could make this process more difficult. In both of these situations, it may not make sense to expand as much as 10 times with a single kettle.

Expanding to 1,000 gallons of production using two 500-gallon (or four 250-gallon) kettles could be preferable. These smaller sizes prevent head weight issues while allowing for individual batch operations for each kettle simultaneously. Loading, mixing, cooking and unloading could be carried out in a series of different kettles.

Even for relatively simple products, such as fully-mixed ketchups or tomato sauces, moving straight to a larger kettle may not be the best choice. Though these sauces can successfully use 1,000- or even 2,000-gallon kettles, a kettle in the 300- to 600-gallon range is generally considered optimum. A kettle in this size range is best with special inclined agitation, which is ideal for mixing products that require a folding or rolling action. Products such as ground beef, soups and pie fillings often fall into this category.

When evaluating your scale-up plan, keep these key considerations in mind

- Product characteristics: Viscosity, texture, and ingredient integrity

- Operational workflow: How batches move from mixing to packaging.

- Space and layout: Available floor space and equipment footprint.

- Utilities: Heating, cooling, and power requirements.

- Personnel and safety: Operator accessibility and maintenance needs.

Confidently Planning for Expansion Using the 10X Rule

Factors beyond your product’s characteristics can also affect your adoption of the 10X Rule. Your line process, workflow, plant layout and available personnel and utility resources will all play a part in your expansion, as will the necessary design choices of the new mixers you’ll need.

But the 10X Rule should be able to help you navigate these questions. By using this rule, you’ll have a better idea how to specifically plan each part of your next expansion, including:

- The equipment you’ll need

- The space that equipment will take up

- The resources the new equipment will require

You’ll be able to expand confidently, knowing that your product’s overall quality won’t be affected by the new size of your operation.

Download our guide to learn more about kettle design and configuration →

Key Takeaways

- The 10X Rule allows production to scale safely, up to 10X the original batch size

- Not all products tolerate that scale due to pressure and handling requirements

- Using multiple kettles can solve head weight and control issues

- 300–600 gallon kettles with inclined agitation are optimal for many mixed foods

- Always factor in plant layout, workflow, and operator resources when scaling

Frequently Asked Questions (FAQ)

Q: What is the “head weight” issue in large kettles?

A: It's the pressure caused by a large volume of product in tall kettles, which can crush delicate ingredients at the bottom.

Q: Can I always use the 10X Rule?

A: No, products that require careful handling or manual oversight may not scale well to that degree in one vessel.

Q: Why choose multiple smaller kettles?

A: This allows more precise control, protects product integrity, and can mirror your original production methods more closely.

Last Updated: 10/15/2025

Comments

Add Your Own Comment