Lee Industries

Sign up to be notified of our new blog posts.

The Return of In-Person Tradeshows: Lee Industries to Exhibit at SNAXPO21 and Other Fall Shows

After a long pandemic hiatus, we are thrilled that several of our favorite live industry gatherings are coming back. Starting in August with SNAXPO21 and continuing through the Fall, Lee Industries will participate in four separate events that bring professionals together to network, learn and see products that can help them improve their operations.

9 Vessel Design Factors that Dramatically Affect CIP Performance

Lee Industries was one of the first vessel manufacturers to introduce CIP capabilities. Since then, we’ve learned a lot about optimizing vessel design to maximize sanitary performance and operating efficiency. Here are several best practices to help you design the best CIP-ready vessel for your operation.

In-Stock Processing Equipment for When Custom-Built Is not an Option

Occasionally, manufacturers have an urgent need for a new vessel and don’t have the lead time required for a custom-built solution. For these situations, Lee Industries is continually manufacturing a range of our most popular models and sizes to make available as in-stock inventory upon completion. Learn more about our in-stock equipment program:

Reviewing the Best Lessons of 2020

One thing we can all agree on is that 2020 was an eventful year. For those of us in the food processing industry, the developments of 2020 may guide our companies’ opportunities, operations and investments for years to come. We thought it would be helpful to revisit a few of the takeaways from last year that can help you be successful in 2021:

Jams, Jellies and Preserves: How to Choose the Right Processing Vessel

As consumers focus on healthy lifestyles and opt for natural products, demand for jam, jelly, and preserve products is growing. This growth, and the arrival of products featuring less sugar and the use of a wider range of spices, herbs and rare or exotic fruits, is leading some manufacturers to consider modifying, upgrading or adding processing equipment to keep pace. Ultimately, their equipment choices can have a significant effect on their overall operational performance. Learn more in our latest blog article:

How Trends in Pet Ownership and Food are Shaping Pet Food Processing Equipment Decisions

More than ever, Americans love their pets…and that is having a major impact on food processing equipment decisions. Our latest blog article takes a look at recent pet food processing trends and highlights important equipment considerations to optimize production efficiency and performance.

Pandemic Raises Value of Cleaning and Sanitizing Features for Processing Equipment

For food, beverage, biopharma, personal care and cosmetic product manufacturers, the need to clean and sanitize processing equipment has always been of vital importance. But in the wake of the coronavirus crisis, cleaning procedures will surely be scrutinized more heavily. Consider these equipment features to help your cleaning and sanitization efforts:

Challenge Accepted: Increasing Evaporation Rates to Accelerate Production

Some of our best work happens in the engineering room. A manufacturer of jams and jellies approached us with a unique challenge, requiring precise calculations to optimize their evaporation rates. See how we helped this client expand their heat transfer area and accelerate production.

Don’t Assume Quality: The Critical Role of a Comprehensive Quality Assurance Program

We’re really picky about the quality of the kettles and tanks we build. Of course, if you rely on processing vessels in your operation, then you also need to be picky about quality, which is why we think it is helpful to understand the process we’ve developed over the years to assure the quality of every vessel before it gets delivered to the customer.

Why Do We Design Tanks with Coil Jackets?

Have you ever wondered why Lee's tanks are designed with coil jackets? See how one of the most important innovations of Lee's 90-year history makes a key difference in throughput and consistency in every batch.

Limitations of Conventional Mixing Systems in Pharmaceutical Topical and Transdermal Drug Product Applications

The inherent nature of high-viscosity pharmaceutical drug products poses real operational challenges to manufacturers. To succeed, processors must seamlessly combine safe and precise ingredient loading, powerful and durable blending, and sterile and efficient cleaning within their operation. Some manufacturers have found it difficult to solve these challenges due to limitations of conventional mixing systems. Here are some of the most common issues with conventional mixing systems in pharmaceutical and other high-viscosity product settings.

Three Food Manufacturing Trends to Watch in 2019

Every year brings new opportunities and challenges to every industry. But for food manufacturing, 2019 will be particularly noteworthy, with important issues facing both food processors and equipment manufacturers alike. This year, new regulations, new technology and new competitors will all play significant roles in shaping the food manufacturing industry.

How to Meet the Challenges of High-Viscosity Mixing

Producing ointments, gels and other high-viscosity products is a challenging process. These stringently regulated products offer a high degree of difficulty for every manufacturer. Selecting the most efficient and cost-effective mixing solution can help you meet those challenges head on, but choosing the right mixing solution may be more difficult than it first appears.

Two Ways Food Processing Kettles Prevent Waste — And Help the World

In food manufacturing, 32.4 percent of all food waste is tied to production issues, much of which could be prevented. However, food production kettles can be a big asset in the fight against food waste, both in their actual function and in the larger application of food safety guidelines in the production process. We've identified two key areas where kettles can make a difference.

See Lee Industries Innovations in Food Processing at Pack Expo International 2018

PACK EXPO International, to be held in Chicago beginning October 14, is the biggest packaging and processing event in the world. We’re always excited to be a part of Pack Expo. Lee Industries is committed to offering the best in custom processing vessel solutions and this is a perfect opportunity to show all we can do to help our customers improve worker and product safety, increase efficiency and reach new levels of productivity.

Crucial Factors to Consider When Expanding Your Food Processing Operation

No matter the size of your current food processing operation, you may someday need to expand. If and when that day comes, you’ll have to address important questions regarding the expansion’s impact on your production.

Lee Industries Receives ISO Quality Management Systems Certification

Lee Industries recently received the ISO 9001:2015 Quality Management Certification, a marker of the company’s ongoing commitment to the highest international standards of quality.

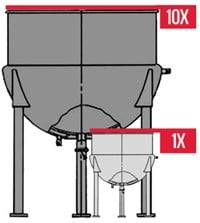

Use the 10X Rule to Guide Your Food Production Expansion

Your food product is taking off and you need to increase your production capacity to keep up. If that is your situation, you may be asking a fundamental question to determine your processing equipment needs: how much capacity can I get from each processing kettle without affecting my product’s quality or consistency?

Lee Industries Explores Blending Options in Latest Production Guide

The latest production guide from Lee Industries explores the differences in the two predominant mixer styles in food production – inclined agitation kettles and horizontal ribbon blenders.